What is Inventory Management?

Inventory management refers to the process of ordering, storing, using, and selling a company's inventory. This includes managing raw materials, components, and finished products, as well as warehousing and processing of such items.

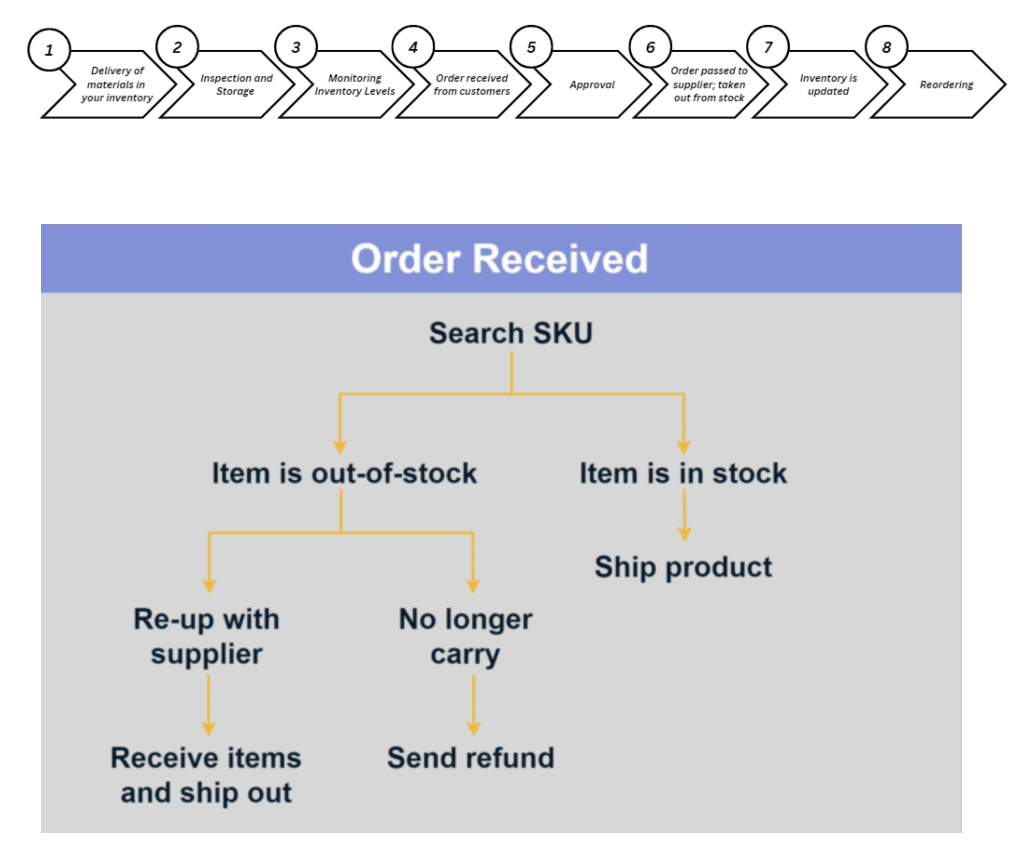

Let’s try to understand the process of Inventory Management:

Types of Inventory Management Methods:

A corporation will employ various inventory management techniques depending on the kind of business or product being examined. The four most popular techniques for analysing inventory are as follows:

- Just-in-Time(JIT) Management - This type of inventory management calls for close coordination with suppliers to ensure that raw materials arrive at the exact time when manufacturing is supposed to start, but no earlier. The objective is to keep just enough inventory on hand to meet demand. Apple is one of the top companies that applies JIT inventory management. It has only one central warehouse in the US and about 150 key suppliers worldwide; it has developed strong and strategic relationships with its vendors. This outsourcing of production made Apple leaner and resulted in slashing costs and reducing overstock. The major risk associated with JIT management arises in case of a sudden increase in demand, as the supplier won’t be able to match it.

- Materials Requirement Planning(MRP) - By calculating the required raw materials, components, and subassemblies, as well as the timing of the final assembly step based on demand and the bill of materials (BOM), an MRP system streamlines the manufacturing production process. Through this approach, we aim to provide answers to three questions: what inventory is required, how much is required, and by when? This technique depends on accurate sales forecasts; thus, manufacturers must have up-to-date sales data in order to anticipate their inventory needs accurately. MRP is useful in both discrete manufacturing, such as for bolts, subassemblies, or automobiles, and process manufacturing, including chemicals, soft drinks, and detergent.

- Economic Order Quantity(EOQ) - This model is implemented by calculating the number of units a company should add to its inventory with each batch order to reduce the total costs of its inventory while assuming constant consumer demand. The holding and setup expenses for inventory are also included. The EOQ model works to make sure that the appropriate amount of inventory is ordered per batch so that a company does not have to place orders too frequently or have an excess of inventory on hand. McDonald’s Corporation uses the EOQ model to determine the most optimal order quantity and minimal costs while ordering materials and products or developing the system of producing the brand’s foods.

- Days Sales of Inventory (DSI) - This is a financial ratio that shows the typical number

of days it takes a business to convert its inventory, which includes finished goods, into

sales. DSI can be understood in a variety of ways and is sometimes referred to as the

average age of inventory, days inventory outstanding (DIO), days in inventory (DII),

days sales in inventory, or days inventory. Additionally, products that are regarded as

"works in progress" (WIP) are counted in the inventory. The number indicates the

inventory's liquidity and how long the current stock of an organisation's inventory will

survive.

DSI = (Average inventory /Cost of goods sold) x 365

For example, Fresh Supermarket is going to work out its DSI for the past 12 months. The Average Inventory value for this period was $20,000, and the Cost of Goods Sold (COGS) was $150,000, so the calculation for DSI is 20,000/150,000 x 365 = 48.7.

Little's Law:

Little's Law is a fundamental concept in supply chain management that helps optimise inventory levels. It states that:

Inventory (I) = Flow Rate (R) * Flow Time (T)

By understanding the flow rate and flow time, the supply chain can ensure efficient product movement from suppliers to distribution centres and finally to customers' doors.

In the context of a consumer goods or quick commerce supply chain, this means that:

Inventory: Represents the number of products waiting to be sold or delivered.

Flow Rate: Indicates the rate at which products are sold or delivered to customers.

Flow Time: Refers to the time a product spends in the supply chain from order placement to delivery.

Example: If you have 250 orders to process (inventory), you can handle 50 orders per day (flow rate), then it will take you 5 days (flow time) to clear the backlog.

Macroeconomics deals in aggregate economic variables such as growth rate of national output, interest rates, unemployment, and inflation. It is called a top down approach as we start by looking at the large picture (the entire economies).

Inventory Turns: Inventory turnover is crucial for profitability. It measures how many times a company's inventory is sold or used in a given period. Maintaining a high inventory turnover helps quick commerce companies reduce storage costs and ensure fresh and in-demand products are readily available for delivery.

Inventory Turns = Cost of Goods Sold (COGS) / Average Inventory

In a consumer goods or quick commerce supply chain, high inventory turnover indicates efficient operations, as products move quickly from suppliers to customers.

ABC Analysis: ABC analysis helps prioritise inventory management by categorising products based on their importance. In this approach:

Class A Items: These are the most important products, often the top 20% in terms of value or demand. Focus on optimising these.

Class B Items: : These products make up the middle 30-35% in terms of value or demand.

Class C Items: These are the less critical products, typically the remaining 45-50%. In a consumer goods supply chain, Class A items might include popular and high-demand products, while Class C items could be seasonal or low-demand items.

Prioritising Class A items ensures that popular and high-value products are always in stock, while Class C items may be ordered on demand, reducing excess inventory and costs.

Role of AI in Inventory Management

Artificial Intelligence (AI) is making waves in how companies handle their inventory. Take Amazon, for instance – they've fully embraced AI in their inventory game. In a nutshell, they use smart computer programs to make educated guesses about what people will buy. This helps them avoid having too much or too little of a product in their warehouses. It's like hitting the bullseye. This saves them money and keeps customers happy because they usually have what we're looking for. AI also helps them plan efficient shipping and keeps our orders safe. Amazon's use of AI in inventory management shows us that it's not just a tech thing – it's about saving money, making things run smoother, and keeping customers satisfied when they shop.

Some of the key benefits of using AI in inventory management include:

- Improved forecasting accuracy

- Reduced lead times

- Automated reorder points

- Optimised warehouse layouts

- Supplier and vendor management

- Quality control and defect detection

Predictive Analysis: Forecasting demand

Inventory management strategies need to adapt to demand variability to ensure efficient operations and minimise stockouts or excess inventory. Here are a few approaches to handle demand variability in inventory management:

- Safety Stock: Safety stock is a buffer quantity of inventory maintained to mitigate uncertainties in demand. By setting appropriate safety stock levels, you can account for demand variability and reduce the risk of stockouts. The safety stock can be determined based on factors such as desired service level, lead time variability, and historical demand patterns.

- Demand Forecasting: Accurate demand forecasting is crucial for effective inventory management. Use statistical methods or forecasting algorithms to predict future demand based on historical data, market trends, seasonality, or other relevant factors. Regularly review and update your forecasts to account for demand variability.

- Reorder Point (ROP): The reorder point is the inventory level at which a new order should be placed to replenish stock. It is typically determined based on the lead time, average demand, and safety stock. With demand variability, consider adjusting the reorder point to accommodate higher or lower demand scenarios.

- Dynamic Replenishment: Implement dynamic replenishment policies that adjust order quantities and frequencies based on current demand conditions. For example, you can use Just-in-Time (JIT) or Vendor-Managed Inventory (VMI) systems to receive inventory as needed or collaborate closely with suppliers to respond quickly to changing demand.

- Collaborative Planning, Forecasting, and Replenishment (CPFR): Collaborate with suppliers, distributors, or customers to share information and align inventory management strategies. By sharing demand forecasts, production plans, and inventory data, all stakeholders can better anticipate and respond to demand variability.

- Safety Lead Time: In addition to safety stock, you can introduce safety lead time to account for potential delays in replenishment due to supply chain disruptions or unexpected events. By extending lead times, you create a cushion to accommodate demand fluctuations during replenishment.

- Continuous Monitoring and Adjustments: Regularly monitor inventory levels, demand patterns, and lead times. Analyse data, identify trends and make timely adjustments to inventory management strategies. Embrace a data-driven approach to identify and address demand variability effectively.

Remember, the optimal approach to handling demand variability may vary depending on your specific industry, product characteristics, supply chain setup, and business goals. Consider utilising a combination of strategies and continuously evaluate and refine your inventory management practices based on real-time information and feedback.

Predicting Demand with AI

The goal of Inventory Management is to stock up and manage inventory efficiently so that we can accommodate future demands. Let’s take up two different scenarios:

- We are currently in a high-demand period and will be moving into a low-demand period, so we want to have a reduced inventory size as demand drops.

- We are currently in a low-demand period and have to stock up inventory for an upcoming high-demand period so that we don’t run out of stock when demands increase.

The problem is, how do we know the amount of inventory we need to have at different times of the year? This becomes especially important in the case of seasonal goods like air-conditioners, heaters, etc.

With the availability of historical data about the demand for goods across the year, we can train predictive Machine Learning algorithms that can forecast the inventory we need to have to match upcoming demands.

ML Algorithms for Demand Forecasting

Given past data on demand, we can train a number of different Machine Learning models to make future predictions on demands, and we can use the outcomes to plan inventory size for upcoming periods. Let’s have a look at some of these models:

ARIMA/SARIMA and other time series forecasting models

There are several popular time series forecasting algorithms used for demand forecasting in inventory management. Some of these algorithms include ARIMA (Autoregressive Integrated Moving Average), SARIMA (Seasonal ARIMA), Exponential Smoothing (ES), Seasonal Decomposition of Time Series (STL), Prophet, Holt-Winters Method, Vector Autoregression (VAR), Neural Networks (such as LSTM and RNN), and Gradient Boosting algorithms like XGBoost and LightGBM

ARIMA (Autoregressive Integrated Moving Average) models are widely used for demand forecasting in inventory management. ARIMA models capture the linear dependencies in time series data by considering the autoregressive (AR) component, the moving average (MA) component, and the differencing (I) component. The AR component captures the relationship between current and past observations, the MA component models the dependency on past error terms, and the I component accounts for trends and seasonality through differencing. ARIMA models can be useful for forecasting demand patterns, identifying trends, and estimating the impact of past observations on future demand.

SARIMA (Seasonal ARIMA) models extend the capabilities of ARIMA models by incorporating seasonality into the forecasting process. SARIMA models consider the seasonal component in addition to the AR, MA, and differencing components. They are effective for demand forecasting when data exhibits periodic patterns and fluctuations over specific seasons or time intervals. By capturing and modelling seasonality, SARIMA models provide more accurate predictions for inventory management, enabling businesses to account for recurring patterns and adjust their inventory levels accordingly to meet customer demands.

SARIMA is one of the most widely used time series forecasting algorithms for demand forecasting in inventory management.

SARIMA is particularly suited for data with seasonal patterns and fluctuations. It extends the capabilities of ARIMA models by incorporating the seasonal component into the forecasting process. By considering both the non-seasonal and seasonal components of a time series, SARIMA models can capture complex patterns and provide accurate forecasts.

Automating Reorder Points

In inventory management, a reorder point is a predetermined inventory level at which an order should be placed to replenish stock before it runs out. It helps ensure that sufficient inventory is available to meet customer demand while avoiding stockouts and associated costs.

In practical terms, think of Starbucks maintaining a reorder point for their coffee beans at, say, 100 kilograms. When their inventory dwindles to this level, it triggers an automatic reorder from suppliers. This safeguards against running out of coffee beans, ensuring they meet customer demand without interruptions. This strategy optimises their inventory, preventing overstock while averting stockouts, ultimately maintaining seamless coffee production at Starbucks stores.

Let’s try to figure out what factors are important while determining the reorder point for a particular product:

- Lead Time (time taken for an order to be delivered after being placed) would be an important factor as it ensures that inventory doesn’t fall below a critical level.

- Average Daily Demand is an obvious factor as it determines the rate at which inventory is declining.

- Safety Stock, which is the extra inventory maintained to account for demand variability or unexpected delays in delivery.

Considering these factors, we now come to the formula for reorder point calculation, which is as follows:

Reorder Point = (Average Daily Demand x Lead Time) + Safety Stock

Using this formula and available data, we can easily determine the reorder point for any particular stock in our inventory.

Manual Reorder point calculation

In manual reorder point planning, you define both the reorder level and the safety stock level manually in the master data record of the respective material. This method has several drawbacks, including Time Inefficiency, Human errors, and Limited Scalability. We shall now look at a more optimised way of determining Reorder Points with the help of Artificial Intelligence

Automatic Reorder point calculation

AI-powered reorder point automation provides a streamlined and effective approach to inventory management. Let’s observe a step-by-step guide to adopting AI-based reorder point automation:

- Collect historical data on product demand, lead times, and other pertinent parameters.

- Using the obtained data, train an AI model, such as a machine learning algorithm. The model should be built to forecast future demand patterns, estimate lead times, and optimise reorder points based on service levels sought and cost considerations.

- Use the AI model that has been developed to forecast future demand and estimate lead times.

- Calculate appropriate reorder points for each product by including expected demand and estimated lead times in the AI model.

AI reorder point automation could provide the following benefits:

- Improved Accuracy

- Time and cost savings

- Improved Customer Service

- Agility and adaptability

Supplier and Vendor Management

Vendor management is a discipline that enables businesses to:

- Keep costs under control

- Promote service quality

- Reduce risks

so they can get more out of their vendors over the course of a deal. Inventory management plays a pivotal role in Walmart's global success story, allowing the retail giant to outshine competitors like Target and Amazon. Walmart's innovative inventory management strategies have revolutionised its supply chain operations, contributing significantly to its competitive advantage.

The Vendor-Managed Inventory (VMI) model is one of Walmart's key inventory management approaches. VMI shifts much of the inventory management burden to suppliers, fostering a collaborative relationship. In this system, suppliers actively manage inventory for Walmart, relying on real-time data to synchronise demand and replenishment planning. This approach has yielded several advantages for both Walmart and its suppliers:

For Walmart:

- Reduced Stockouts: VMI minimises the risk of running out of stock, ensuring products are consistently available to customers.

- . Lower Inventory Costs: With suppliers managing inventory, Walmart can reduce storage requirements and carrying costs.

- Enhanced Product Visibility: Suppliers can place representatives in stores, ensuring their products are displayed optimally and increasing sales.

- Data-Driven Decision-Making: VMI relies on real-time data, helping Walmart make informed decisions about inventory levels and demand forecasting.

For Suppliers:

- Improved Demand Forecasting: Access to Walmart's data enables suppliers to accurately forecast demand, reducing the risk of overstocking or undersupplying.

- Long-Term Partnerships: VMI fosters partnerships between suppliers and Walmart, resulting in in-store promotions and preferred product placements.

- Efficient Inventory Management: Suppliers can optimise their inventory levels and reduce storage costs.

Walmart's adept utilisation of the Vendor-Managed Inventory (VMI) model exemplifies the paramount role inventory management plays in its sustained global dominance. By seamlessly blending cutting-edge technology with robust supplier relationships, Walmart ensures its shelves remain well-stocked, customers consistently find what they need, and inventory costs are optimised.

Managing the ordering, receiving, reviewing, and approval of things from suppliers is part of the procurement management process(a way to buy things from outside vendors). Supplier management is concentrated on how the suppliers affect the life of the business, while vendor management is focused on pricing comparisons and contract negotiations.

The form of vendor management used in the majority of company settings today is adequate for successfully managing a small number of vendors. However, as the demands change, more sophisticated administration is needed for a whole vendor ecosystem in larger businesses. The sheer volume of contacts, contracts, products, tasks, and other items in this environment far exceeds customary procedures. Fortunately, AI excels at handling data, and new tools are being developed to modernise vendor relationship management.

Briefly put, procurement is a difficult process that requires handling enormous amounts of data, navigating constantly changing market conditions, minimising risks, and improving supplier relationships. AI is a useful tool for procurement teams because of the enormous amount of data and the necessity to analyse it effectively.

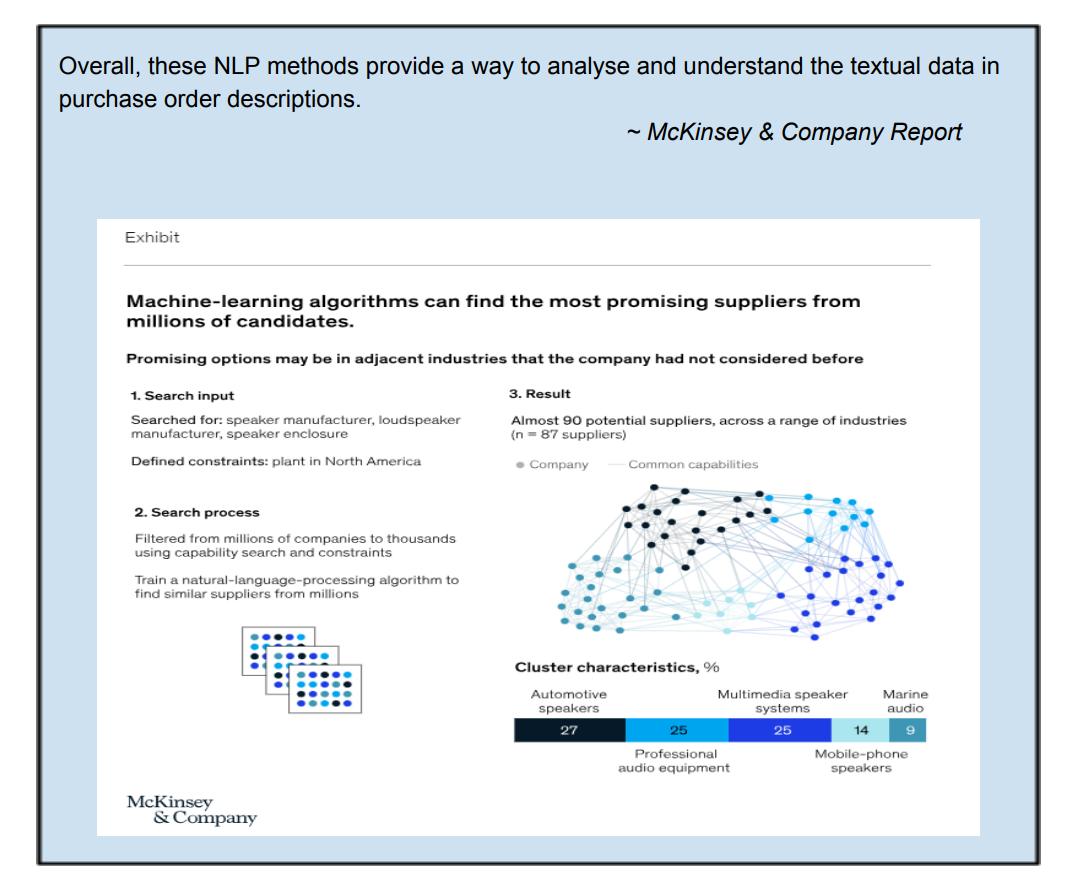

A more effective method of supplier finding is now taking shape. A new generation of technologies scans millions of suppliers in a fraction of the time by combining human expertise with an AI algorithm, dramatically improving the supplier identification process. A category expert clearly and concisely characterises the intended good, service, or manufacturing capacity, together with any limitations like geography. Millions of suppliers have access to often updated source data from a range of proprietary, open-source, and commercial databases, some of which are regionally and globally focused. A natural language processing (NLP) algorithm is then iteratively trained by the category specialist to search through the supplier descriptions in the combined data set. The NLP algorithm quickly reduces the list of potential suppliers to a select handful that meets the sourcing expert's requirements. A selection of potential providers may be found from a database of millions of suppliers in just a few hours thanks to this iterative technique, which enables search engines to work with previously unheard-of speed and accuracy(Exhibit).

Let's break down the two NLP methods mentioned in the text:

- FastText: FastText is a technique used for word representation and text classification. It creates word vectorisations, which means it converts words into numerical representations that can be understood by a computer. These representations capture the meaning and context of words. In the context of supplier discovery, FastText was likely used to convert the textual purchase order descriptions into numerical representations that could be processed and analysed by machine learning algorithms.

- HDBScan: HDBScan stands for Hierarchical Density-Based Spatial Clustering of Applications with Noise. It is a clustering algorithm used to group similar data points together. In the case of supplier discovery, HDBScan was applied to the word vectorisations created by FastText. The goal was to identify clusters of similar purchase order descriptions, indicating potential similarities between the suppliers associated with those orders. By clustering the word vectors, HDBScan helps identify patterns and groupings that can assist in the discovery of new suppliers.

AI in Supplier Performance Management

An essential component of supply chain management and procurement is supplier performance management. In order to make sure suppliers fulfil quality, delivery, pricing, and other contractual obligations entails tracking and evaluating their performance. AI's potential to increase productivity and decision-making in supplier performance management is enormous.

Predictive analytics enabled by AI can forecast supplier performance, enabling businesses to foresee and reduce potential risks and interruptions. AI algorithms can provide insights into supplier behaviour, such as delivery delays or quality issues, by analysing past data and external circumstances, allowing preemptive steps to be performed. By connecting with numerous data sources, such as IoT devices, supply chain management systems, and external data streams, AI can also make it easier to monitor supplier performance in real time. Automated alarms can be sent off if performance thresholds are exceeded, allowing for prompt problem-solving and proactive problem management. AI can be used to compare a supplier's performance to industry norms or those of other vendors. The areas where suppliers need to improve can be determined using this data. AI can be used to track a supplier's adherence to agreements, rules, and other specifications. Problems can be avoided by using this information, and suppliers' duties can be confirmed.

Named Entity Recognition (NER), a widely used NLP algorithm, recognises and classifies particular entities inside the text, such as supplier names, product names, and contract terms. In order to analyse and evaluate contractual commitments, this assists in automating the extraction of crucial information from supplier contracts. Another significant NLP algorithm that may evaluate the sentiment represented in customer reviews or emails is sentiment analysis. AI systems can identify if a text's sentiment is favourable, negative, or neutral by examining its tone and substance. This examination offers information on general performance, prospective supplier problems, and customer satisfaction. A huge corpus of unstructured text data can also be used to find important topics or themes using Topic Modelling methods like Latent Dirichlet Allocation (LDA). This assists in identifying recurrent problems, new patterns, or shared difficulties in supplier contracts, correspondence, or customer comments.

A substantial amount of potential exists for improving transparency, traceability, and automation in supplier performance monitoring when AI, blockchain technology, and smart contracts are combined. A decentralised and unchangeable record of transactions and interactions is provided by blockchain. On the other hand, smart contracts are self-executing agreements with predetermined terms and conditions. By combining AI and blockchain technology, an audit trail of supplier performance data that is both transparent and impenetrable can be created. This guarantees that the performance measurements, assessments, and any related actions are documented in a secure and impermeable way. AI-driven performance assessments can be recorded as blockchain transactions, giving a reliable and auditable history of supplier performance. Based on AI-driven performance evaluations, smart contracts can automate the performance of prescribed activities. A smart contract, for instance, may be programmed to automatically enact penalty provisions or alert concerned parties if an AI system identifies a supplier as not meeting predetermined quality criteria. Since all parties can rely on the transparent and automatic execution of contractual duties, this lowers the need for manual involvement and the likelihood of disputes. The algorithms employed in blockchain-based and smart contract-driven AI-driven supplier performance management are determined by the particular needs of the organisation. To analyse performance data and produce insights. These algorithms can categorise providers according to their performance, forecast performance trends in the future, and suggest the best course of action.

One area where machine learning excels is in analysing historical data related to procurement incidents, such as fraud and theft events involving external suppliers. By training machine learning models on this data, organisations can develop a procurement risk score that helps identify potential high-risk supplier partners. These models analyse attributes of past incidents to uncover patterns and similarities, enabling procurement professionals to take proactive action before a procurement incident occurs.

Risk modelling techniques, such as decision trees and random forests, are commonly employed in developing procurement risk scores. Decision trees break down the decision-making process into a series of sequential questions, leading to the identification of high-risk suppliers based on their attributes and historical incident data. Random forests, on the other hand, combine multiple decision trees to create a robust and accurate risk assessment model. By leveraging these techniques, organisations can make data-driven decisions, strengthen their supplier screening processes, and safeguard against potential risks.

In addition to risk management, machine learning can significantly enhance communication between procurement professionals and suppliers. By analysing communication patterns within various organisations, machine learning models can predict which suppliers are more likely to respond quickly to requests or questions. This capability allows procurement professionals to communicate more effectively with suppliers, ensuring prompt and efficient resolution of supplier-related issues.

AI algorithms can enable businesses to implement dynamic pricing strategies based on real-time market conditions and customer behaviour. By continuously analysing market signals and customer preferences, AI systems can adjust pricing in response to changes in demand, inventory levels, or competitor pricing. This dynamic pricing approach helps businesses optimise revenue and maximise profitability

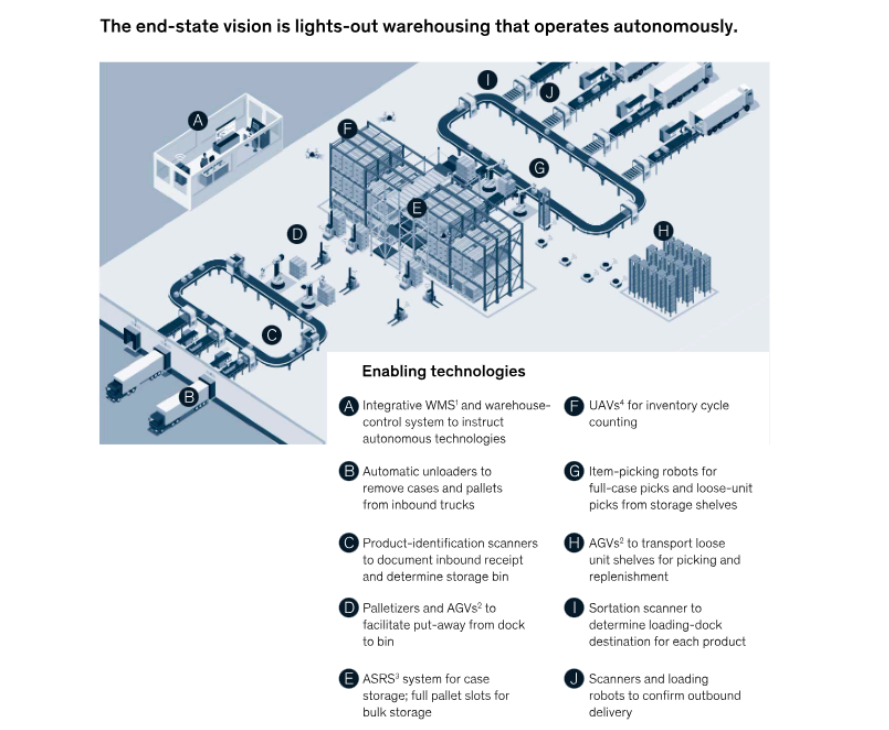

Warehouse optimisation using AI

A series of actions that ensure that items enter and exit the warehouse smoothly are known as warehouse operations. Well-organized warehouse operations have turned into a crucial source of competitive advantage for supply chain organisations since the introduction of e-commerce and the expanding significance of warehouses in the client purchasing process.

The key work activities in warehouse operations can be grouped into six main categories:

- Receiving - When incoming goods are received, checked, and labelled.

- Put-away - Placing the received goods in the storage area

- . Storage - Tasks related to organising and operating the warehouse storage area to be space-efficient and process-efficient.

- Picking - Automated or manual picking or orders, B2B or directly to the consumer.

- Packing - Picked items are packed in boxes safely and with as little air as possible

- . Shipping - The packed boxes are transferred to the transport company and checked out.

Algorithms are used in machine learning to "learn from experience" and arrive at useful warehousing decisions. It recognises trends in sensor data and suggests quicker replenishing of virtually depleted inventory, shorter walking distances, and better inventory arrangement. Wearable technology for warehouses is made possible by some AI features. Voice-picking is made possible by natural language processing, which makes work safer and more hands-free for employees. With the aid of computer vision, barcodes may be automatically recognised by smart glasses' cameras. Computer vision is also used via cameras that are strategically positioned throughout the warehouse to enable end-to-end product tracking. Finally, robotics enables AI to roam around in the actual world and give it a tangible presence. The abilities of AI robots can include everything from choosing tasks to transporting merchandise throughout a warehouse and loading or unloading a pallet.

Some other ways in which AI is reshaping warehouse management are mentioned below:

- . Productivity: Increase the effectiveness of pick-and-pack operations. Because ML enables managers to capitalise on the effectiveness of the most productive pickers to produce a completely integrated system-directed solution, processes are transformed and simplified. The interface for operating rules to be used in the smart warehouse and a suggested SKU strategy based on past and future sales data are already included in slotting software. While humans still modify slotting tactics based on their own expertise and experience, this practice will eventually give way to ML algorithms.

- Communication: Artificial intelligence (AI) and machine learning algorithms allow automated systems to interact at a rate that is several times faster than that of human operators. Many warehouse-related tasks are already automated, but by combining IoT-enabled devices into these operations, speed and accuracy will be greatly increased. All components of your system can engage in a discussion that includes system monitoring and control thanks to wireless cloud data transfers. Deep learning techniques also give computers the ability to continually analyse the data streams produced by these components, enabling them to make improvements and modifications in an integrated WMS (Warehouse Management System) in real time.

- Wages: Payroll costs will be cut, initially being compensated by the necessary technical expenditure. The labour costs aspect of how AI will change warehouse management is the most disputed. At this point in its development, robot aid barely affects how things are done now. Though 30% of UK warehousing jobs will be totally automated by 2030, AI has the ability — and will have the potential — to increase machine handling capabilities. The most likely industries for automation are those that involve data gathering, processing, and predictable physical operations. Established eCommerce businesses assert that rising automation will increase the overall scope of their business operations and hence generate jobs, but this will only become clear over time.

- Warehouse logistics:Processing times and operator error reduction can boost productivity and overall effectiveness. Using AI to optimise logistics will change warehouse management as well. Think about figuring out how many pallets need to be moved each day, how much equipment is needed to handle that movement, and how much labour is necessary to complete that movement. In the past, these estimates were based on the operator's expertise and SKUs (stock-keeping units). ML algorithms now make it possible to forecast and manage stock movement in great detail to improve material handling.

- Inventory: Free up resources that were previously devoted to inventory management for other business expansion areas. By tracking products with digital tags and enabling more precise and accurate inventory control, radio frequency identification (RFID) replaces paper trails and barcode scanners for inventory organisation and control. RFID scanners do not require direct line-of-sight control because the system employs radio waves to convey data; instead, they are aimed in the general direction of a product to identify it and direct its movement into, out of, and around the warehouse

Quality Control using AI

Products are more likely to break or wear out before their guarantee period ends when supply chain quality management is subpar. Depending on the type of business, there are a lot of failures that might happen after a product leaves a manufacturing plant. Customers who are required to return goods eventually stop favouring the store where they made their purchase. In the end, supply chain quality management aids in preserving a company's reputation. The degree of external supplier input control will determine how often returns and potentially dangerous product defects are to occur.

Keeping a competitive edge in the market and lowering operating expenses require quality management in the supply chain for these reasons. Waste becomes more common than is acceptable in the absence of quality management. Your business may prevent and address supply chain concerns by reviewing the elements of quality management systems.

AI has a lot to offer in terms of logistics support for quality control. It can inspect products as they enter and exit your fulfilment processes and look for flaws, negligent packing techniques that might put products in danger, invalid labelling, and other things. It can also keep an eye on the software that helps you manage your business and guide you in making the best decisions by analysing data. AI may assist in making sure your order products are up to par, whether it be through incoming procedures, daily inspections, picking and packing activities, pre-shipping jobs, or other intermediary steps.

Among the most significant ways AI might enhance quality control logistics are:

- Keeping track of inventory levels and expiration dates to determine when to remove and replace products.

- By recording the condition of inventory goods in your warehouse or inventory management system, you may reduce wasted inventory and lost income.

- Highlighting inconsistencies in item weights or dimensions so your warehouse staff can address any issues and stop defective items from progressing further along your supply chain or fulfilment process.

- Identifying flaws in your warehouse hardware, integration links, or warehouse management systems (WMS) to prevent problems from turning into downtime and quality control difficulties.

- Notifying staff members of missed quality management system steps by highlighting them in SOPs, product checklists, or other procedural documents.

- Identifying flaws using data from your enterprise resource planning (ERP) solutions and client feedback.

- Enables objective, data-driven decision-making, relieving your staff of the need to anticipate or hazard a guess as to what should be done when a problem arises with one of your products.

- To reduce the possibility of items being damaged throughout the fulfilment process, optimise the picking and packaging waves, walking routes, and station traffic.

Use Case of AI in Quality Control:

Anatoli Gorchet, co-founder and CTO of Neurala, a provider of AI vision software, outlines the method behind conventional industrial inspection processes utilising machine vision to help demonstrate how AI is transforming machine vision. In the first phase, a professional selects the camera-captured elements (such as edges, curves, corners, colour patches, etc.) that are pertinent to the inspection. The expert then develops a rule-based system that specifies, for instance, how much "yellow" and "curvature" designate an object as a "ripe banana" in a packaging line. Based on the expert's input, the resulting system automatically determines whether the product is what was anticipated. Even though it has proven quite successful, there are specific situations when it renders machine vision useless. Gorchet noted that it might be challenging to distinguish between good and terrible items in situations where the differences are highly qualitative, nuanced, or variable.

AI has a role in this situation. The AI-powered software may learn which elements are significant on its own and establish rules that identify the combinations of attributes that constitute excellent products rather than having the machine vision system rely on the rules created by the expert. Users no longer have to manually create a machine vision model for each production situation thanks to neural network learning algorithms, according to Gorchet. "They just need to gather the right data and train the model with it, whether it's for fruits, aeroplane parts or ventilator valves."

The standard deep learning system, Gorchet explained, "once these pictures are collected, has a training regimen that, when fed a good quantity and variety of data, trains a model that ends up being really good at coming up with precise, low error, confident classifications." Of course, fresh data collecting, training, and deployment procedures will need to be carried out to create a new model if the line changes to a different part or product.

A novel type of DNN is being investigated for industrial quality inspections to simplify this procedure. These DNNs are referred to as "lifelong" or "continual" learning DNNs (L-DNNs). Gorchet claims that these L-DNNs separate feature training from rule training in order to add new rule knowledge instantly. "Like conventional DNNs, they need a slow learning of features based on a large balanced set of data—which includes equal amounts of images of good valves as well as every possible type of defective valve; but unlike conventional DNNs, they do not include rule learning at this stage and therefore do not require images of all known valve defects," he said.

Actually, the photos don't even have to be of valves as long as they share characteristics like curves, edges, and surface characteristics. This data set does not have to be industry-specific and can be rather general. As a result, the L-DNN provider only needs to create the model once, and the manufacturers are unaffected in any way.

This indicates that for the system to acquire a set of rules for what a good valve is, manufacturers only need a limited amount of photos of good valves. According to Gorchet, L-DNNs have the ability to learn from a single presentation of a small dataset using just high-quality data and then provide advice to the user when they come across an unusual product. "An L-DNN training regimen can go over a set of tens of images, build a prototypical understanding of the object, and be ready to be deployed and reconfigured if and when production changes," the expert claimed.

Future Prospects

Looking further into the future, the integration of natural language processing (NLP) and computer vision (CV) technologies holds great potential for advanced inventory management:

- Voice-Enabled Inventory Control: NLP can enable voice commands and conversational interfaces for inventory management systems. Users can interact with the system using natural language, making inquiries about stock levels, placing orders, or querying inventory-related information. This streamlines the inventory management process and allows for hands-free, intuitive control.

- Sentiment Analysis and Customer Feedback: NLP can analyse customer feedback, reviews, and social media posts to extract insights regarding product preferences, satisfaction levels, and emerging trends. Integrating sentiment analysis into inventory management systems enables businesses to adjust their inventory strategies based on customer sentiment, leading to more targeted and customer-centric inventory decisions.

- Intelligent Product Categorization: NLP techniques can automatically categorise products based on textual descriptions, reducing manual effort and ensuring consistent classification across different inventory systems. This enables better organisation and easier searchability of inventory items.

- Visual Recognition for Inventory Tracking: CV technology can be employed to track and identify inventory items through visual recognition. This includes barcode scanning, object detection, and image recognition to accurately monitor stock levels, locate specific items, and automate inventory counting processes.

- Image-Based Demand Forecasting: CV techniques combined with demand forecasting models can leverage images and visual data to predict demand patterns. For example, by analysing images of fashion trends or product usage, AI models can forecast demand for specific products or styles, assisting businesses in proactive inventory planning and stock optimisation.

- Shelf Monitoring and Optimization: CV-based systems can monitor shelves in real time, ensuring proper stocking, identifying misplaced items, and providing alerts for restocking. This technology helps optimise shelf layouts

Nordstrom, a luxury department store chain renowned for its high-end fashion and exceptional customer service, recently launched a new inventory strategy — that there is no inventory. They've developed a new store concept called Nordstrom Local, which is a small area where they focus on the consumers rather than the product. Customers want quick and easy shopping experiences, and Nordstrom capitalised on this. Alteration services, personal styling, nail salons, beverages, online order pick-ups, and no inventory are available at the store. By establishing this store concept, they are demonstrating their dedication to their clients and providing them with what they truly desire.

The future of inventory is going to be flooded with updates in technology. From virtual reality to artificial intelligence, to digital signage, and even inventory-less stores, there are constant iterations made in this industry to accelerate business and attract customers. And it’s only growing from here.